Hoover are instrumental in helping us develop a water management system that can scale and grow as the development expands.

Mike Smith, Operations Manager

WVID

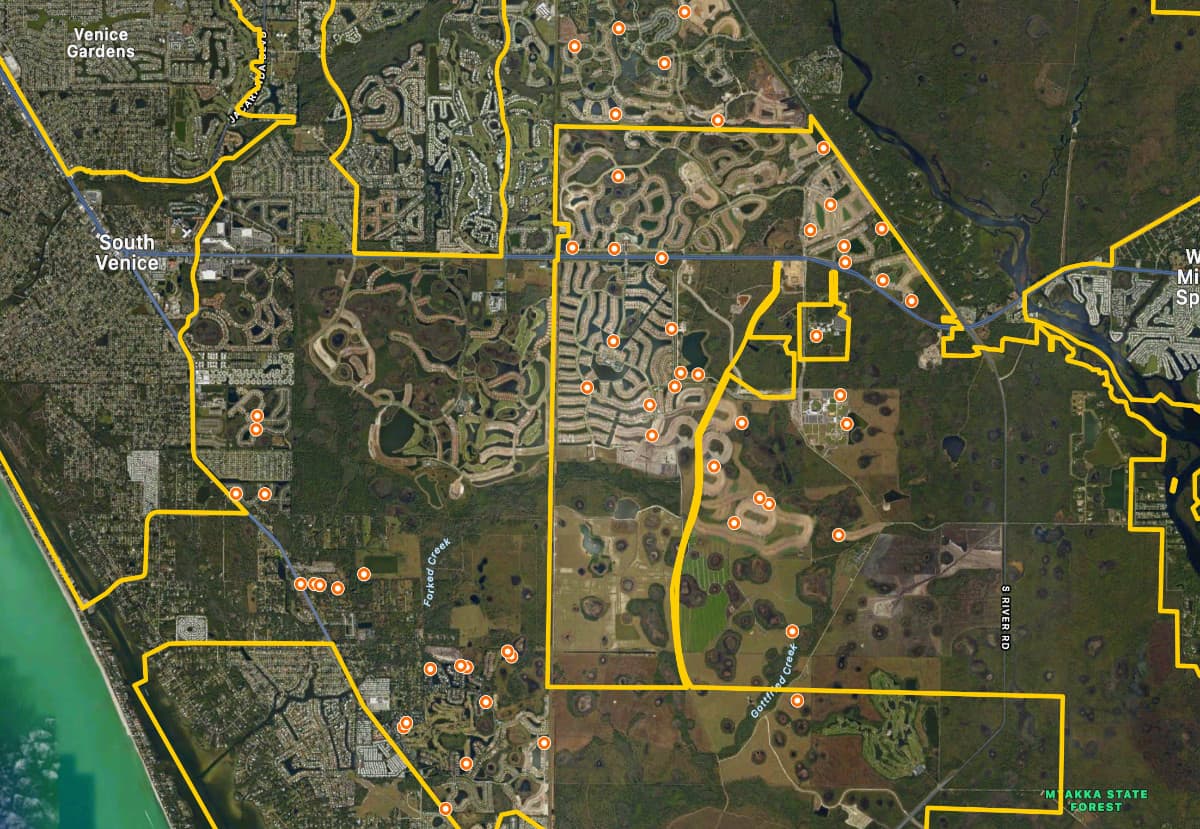

Location: Wellen Park

Client: West Villages Improvement District

Market: Property Development

Wellen Park is an 11,000 acre master-planned community that is projected to house over 60,000 residents.

Providing a complete water management solution that supports the park’s infrastructure and encourages growth.

Work in partnership with the WVID to create intelligent water transfer systems that support sustainable growth.

A network of interconnected pump stations, managed using intelligent software that provides 24/7 oversight and control.

Every drop of water that moves through the 11,000 acre development touches one of our systems.

Wellen Park is the fourth-fastest growing residential community in the US. Located in Sarasota County, Southwest Florida, it’s currently home to approximately 7,500 residents.

Set on an 11,000 acre site, the community will house more than 60,000 residents when it’s finished. Wellen Park is also home to the Atlanta Braves’ spring training ground.

The development is run and managed by a specially-designated improvement district (the WVID), and Hoover have been their irrigation partner since work first began in 2006.

We were originally commissioned to design and install a single pumping station to supply the Grand Paradiso community with water, but our involvement has grown as the project has flourished to include water transfer solutions for dozens of acres of manmade irrigation lakes and a wastewater treatment plant.

Over the last 16 years, we’ve helped to design, install and manage the over 40 best-in-class pump stations and POCs needed to manage Wellen Park’s water needs and this number continues to grow. Hoover equipment is moving millions of gallons between various water sources so that individual communities can stay on top of their irrigation needs and recharge or replenish wells and lakes as water levels change throughout the development.

As of 2022, we are also helping the team to move water from a new wastewater treatment plant to a dedicated irrigation lake that’s designed to help Wellen Park conserve water, meet their sustainability targets and save money.

But it's not just about the physical infrastructure that we've built for Wellen Park. We’re also helping the WVID save time and money by implementing Flowguard technology to run their water management systems. In short, we help to keep the development functioning, and make sure that the landscape is healthy and thriving.

Hoover are instrumental in helping us develop a water management system that can scale and grow as the development expands.

Mike Smith, Operations Manager

WVID

Managing 11,000 acres of manicured landscape and 22,000 homes isn’t easy. Residents, construction companies and the development’s own marketing department all expect green spaces to look lush and inviting at all times, but that’s a tall order in Southwest Florida, where hot summers and dry winters make year-round irrigation a real necessity.

As you can probably imagine, the team that manages the Wellen Park development spends a lot of time (and money) moving vast amounts of irrigation-quality water around the site.

Wellen Park’s management team are also under a lot of pressure to conserve as much water as they possibly can. Hydrologists employed by the South Florida Water Management District (SFWMD) model water use for the development, and the SFWMD then assigns water use permits to allocate an amount of water for landscaping use.

The current water use allocation for the 11,000 acre Wellen Park site is approximately 9 million gallons a day, but that seemingly-huge quantity of water is quickly eaten up by the various developments, and the management team has to keep close tabs on this right across the development – no easy feat when you’re talking about pump stations that move upwards of 4,000 gallons a minute.

Most of all, Wellen Park benefits from hands-on help and support with a number of daily challenges, including:

Lake Level Management

The level of various man-made irrigation lakes have to be monitored so that they can be augmented as water is used or moved throughout the development - and drained in the wet, summer months when there’s a risk of them over-filling.

Pump Station Management

Somebody has to keep tabs on the flow rates at various pump stations across the development, preempt any problems with the machinery required to pump millions of gallons of water across the development and make sure that water is flowing around the clock.

The Fine Detail

There’s also a pressing need to keep on top of the fine detail – things like water salinity, as salt water can kill off the lush vegetation people expect to see on the development, and that’s a lot of responsibility for one team to handle.

The Wellen Park development is large and complex. It's also evolving on a month-by-month basis. To keep pace, we've implemented a flexible plan that allows us to design, build and deploy more and better pump stations as the development's demand for water grows.

Our plan also accounts for the changing needs of a rapidly-growing development that's roughly the size of Fort Myers. That means anticipating the need for more water treatment plants, planning for and building the infrastructure needed to support billion-gallon irrigation lakes and designing systems that are capable of shuttling vast amounts of water from A to B.

It's not just about the hardware either: Our plan also accounts for the management of Wellen Park's water resources, and we've helped the WVID save time and money by implementing Flowguard technology to manage their water management system. In short, we help to keep the development functioning, and help the landscaping thrive.

To help the Wellen Park Improvement District stay on top of their irrigation needs, we’ve designed a sophisticated system that draws from a combination of 40-60 acre irrigation lakes and a handful of wells that are used to augment those lakes if required, during the drier, winter months.

At last count, this system relied on 40-plus Hoover pumping stations and POCs, but it’s growing fast. New pump stations are commissioned every time the development grows and we’re currently working on a very large, four-pump station that’s capable of pumping approximately 4,000 gallons of water a minute.

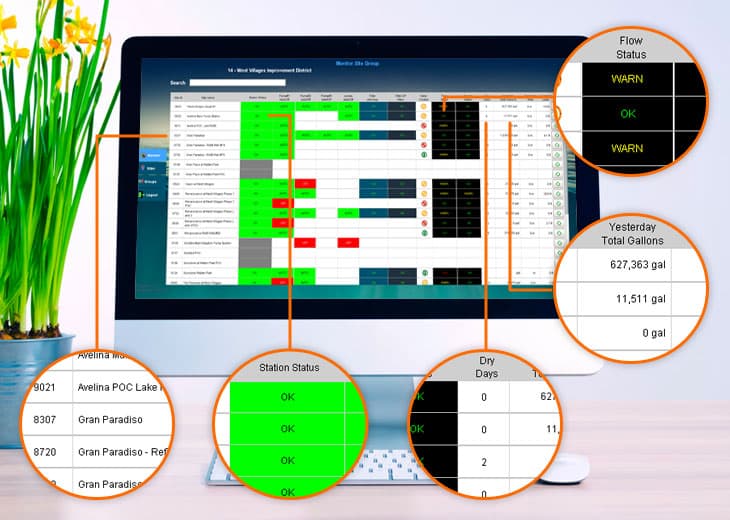

Many companies are capable of building a large irrigation system. What makes this solution particularly special is the intelligent management software that underpins it. Each and every pump station is connected to Flowguard; our patented smart water management tool.

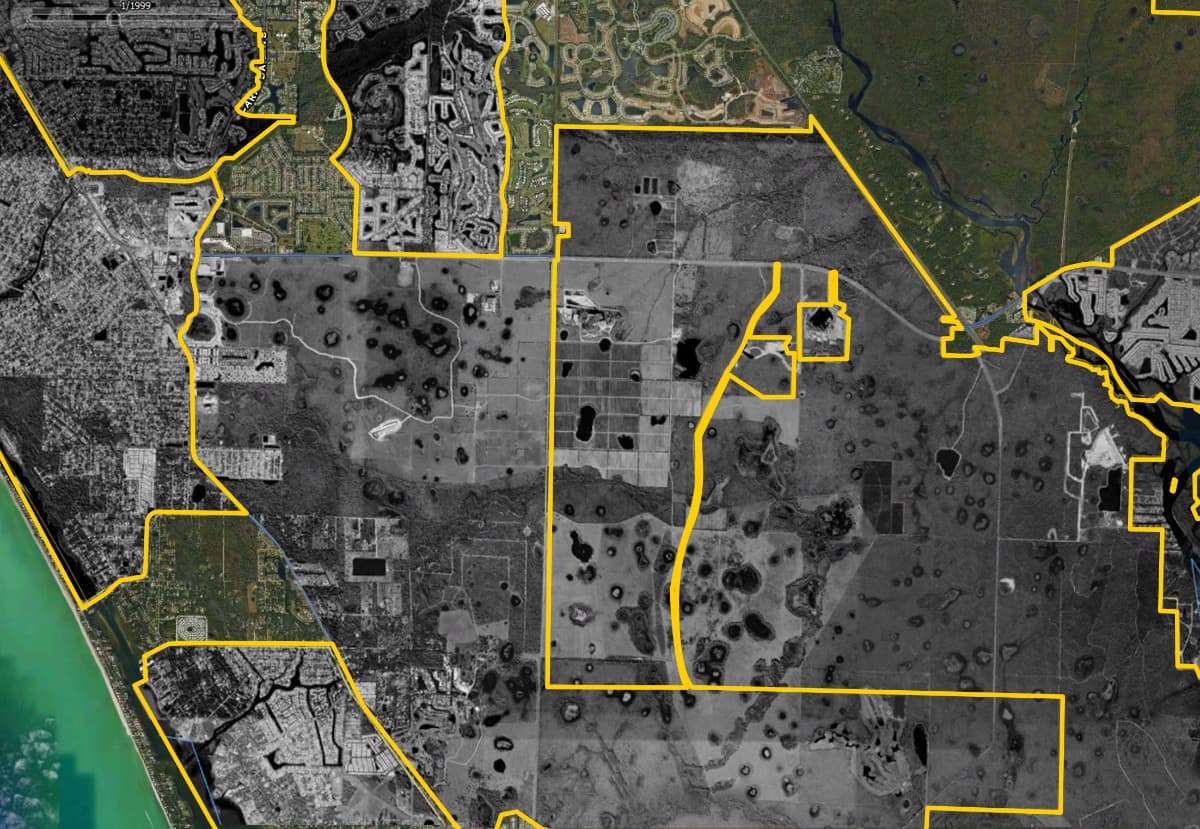

2022

2022

1992

1992

Hoover thinks ahead and helps us find solutions to problems that inevitably crop up when you’re managing a large acreage. They fly by our wingtips.

Mike Smith, Operations Manager

WVID

This system lets the operations team stay on top of everything: They get instant notifications if and when an issue pops up, they have 24/7 access to dashboards that tell them about water use across the development, and they only need a phone and an internet connection to log into the system and dig through reams of data about flow rates, water quality, pump conditions, lake levels and water schedules.

Say someone accidentally severed one of the 12-inch mainlines that feed various developments around the site. A member of the management team could log straight into the system and shutdown the pump station that fed it: Saving thousands of gallons of water and preventing a costly catastrophe and making sure the development in question doesn’t accidentally blow through its daily allocation of irrigation water.

The system can also do this automatically, if critical incidents occurred overnight which means that the WVID can rest easy – content in the knowledge that problems will be handled for them.

Flowguard’s remote control system also enables the team managing Wellen Park to reroute water if a pump station is temporarily off-line, or automatically send alerts when one or more irrigation lakes are starting to run low – giving people the time to start diverting recycled grey water to high-priority areas that can’t be left dry.

As anyone managing a similar development will know, problems are inevitable. Pump stations will go offline, lines will rupture and droughts will strike when you least expect them, but we don’t think that unexpected faults or issues should have the potential to completely derail your system.

In fact, we think that planning for - and successfully mitigating - outages and other problems is the only responsible way to manage an irrigation system of this size, which is why we spend a lot of time working out how to manage worst case scenarios.

We’ve been working side-by-side with the Wellen Park team for some time now.

When we first broke ground, we were building a single pumping station and we’ve definitely grown alongside the development; designing increasingly sophisticated systems as their needs have changed and new challenges have arisen.

Working hand-in-hand with the team has given us a unique opportunity to propose, design and implement solutions that push the envelope, and save the development large sums of money.

It’s great to see the team at Wellen Park making good use of our Flowguard system. We’ve always been of the opinion that water management systems are only effective when they’re managed correctly, and good management requires a detailed data set.

We’re very happy to see the team log into and leverage Flowguard’s dashboards for reporting, management and maintenance on a daily basis, and we know that they love the control it gives them too. It’s critical to the continued functioning of their operations.

As the development continues to grow, we’ll work closely with the management team to ensure they can always irrigate their green spaces efficiently, and be able to move the water. We look forward to a future full of innovation, and can’t wait to see how they’ll challenge us next.

The City of North Port at Wellen Park have a very interesting video tour of the water treatment plant that illustrates the complexity and size of the operation there.