The automated nature of modern irrigation systems is such that many people make the mistake of assuming the system they rely on works on a ‘set and forget’ basis. In this article we discuss how it's possible, even if you're not a pro, to carry out basic maintenance checks that will keep your irrigation system functioning more smoothly day to day.

While "set and forget" is probably a lot closer to the truth than it’s ever been – in terms of the degree to which a smart irrigation system can be self-regulating and can spot and flag up issues in real time – there’s still no substitute for vigilance when it comes to getting ahead - and staying ahead - of the curve.

An understanding of the possible issues that can arise across any irrigation system, coupled with the knowledge of where to look and what to do if something is wrong, can save time and money over both the short and longer term.

For anyone in charge of overseeing large-scale irrigation operations for a golf course or residential community irrigation, the importance of a functional system in good repair is hard to overstate, particularly in a part of the world like Florida. But even for smaller scale operations, regular, simple checks can keep a system functioning more efficiently and forestall expensive repair bills.

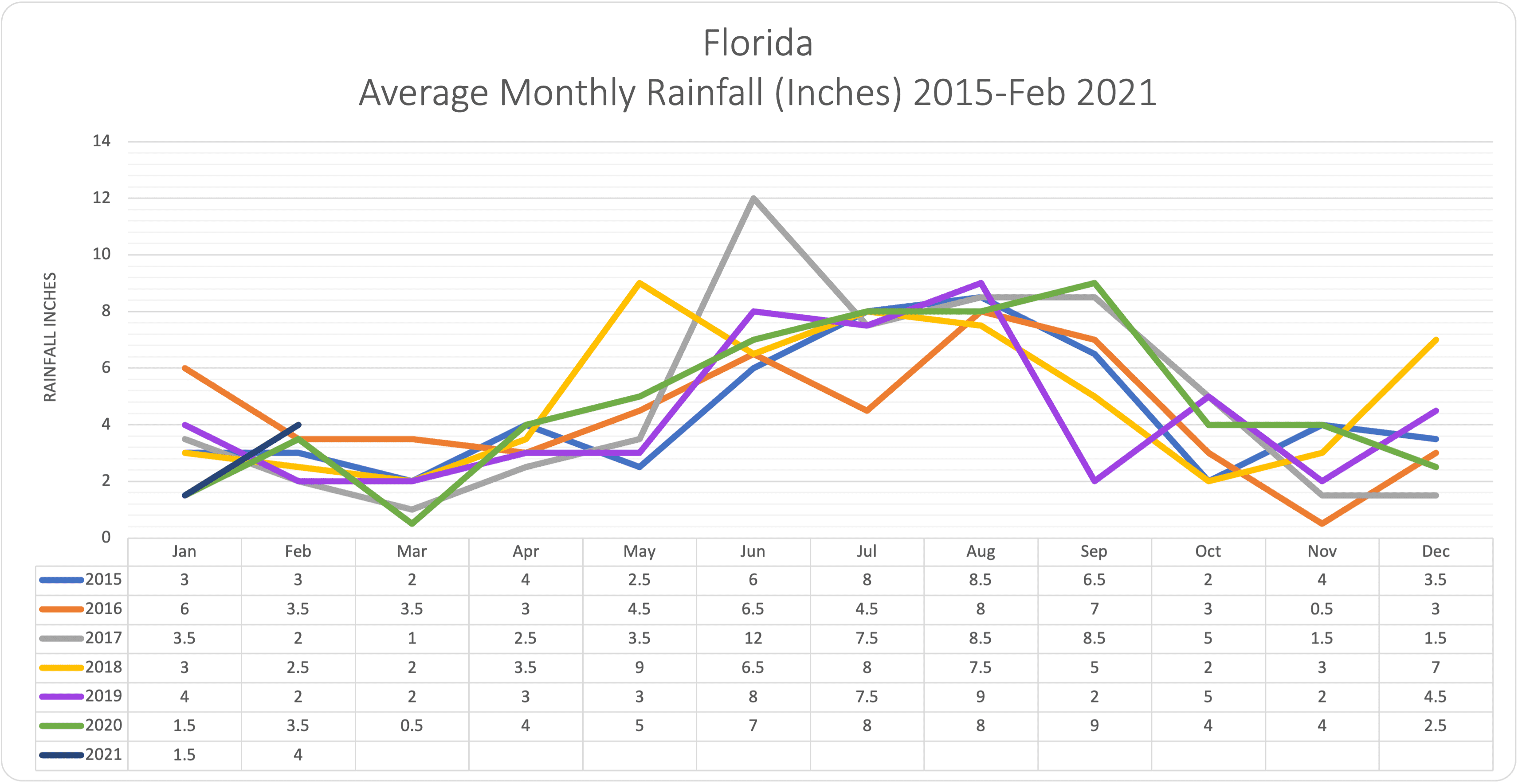

The fluctuations in rainfall across the seasons are dramatic here to say the least! They create a situation in which irrigation must be not only consistent, but highly focused and controlled.

Too much water – a result which is just as likely to follow from malfunctioning irrigation equipment as too little – can be a disaster for the landscape, but the good news is that there are relatively simple measures you can take to maintain your irrigation system without having to call in the professionals too often or finding yourself having to invest in major repairs or upgrading work.

In terms of landscape management, inspection and maintenance of the irrigation system is as vital as any other form of maintenance. Many people feel reluctant to take it on themselves, however, either because they mistakenly believe, for example, that irrigation can be left to take care of itself once it's set - or they fear that spotting and dealing with any problem is something only a professional can take care of.

The key to understanding a regular in-house maintenance regime is that it involves spotting the kind of smaller scale problems that can be dealt with quickly and simply, before they have the chance to become larger problems. Even if the problems spotted are beyond the ability of a non-professional to correct, the fact that they have been highlighted at the earliest possible stage will cut the cost of any repair work needed.

The easiest way to put together and maintain a maintenance and repair checklist is to break the numerous stages involved down into individual tasks, rather than viewing the whole of the system as something to be checked and maintained in one sweep – something which the vast majority of people would find more than a little overwhelming.

The first and simplest means of checking the operation of your irrigation system is to take a good look at the landscape. Tell-tale signs that something is going wrong somewhere include pooling water, dry patches, excess run off and boggy areas.

Anything out of the ordinary is a symptom of something going wrong. It may well be as simple as the timer system needing a reset, but it could also indicate deeper problems, such as sensors in the turf not working, pumps over or under-pumping and pipes leaking underground.

Although you may never personally carry out any of the following physical checks - such as flushing or cleaning sprinklers for example - it's useful to give yourself a basic understanding of some of the maintenance activities your landscape contractor or irrigation maintenance team will (or should) be carrying out on a regular basis. Being better-informed could give you useful insights into whether you're getting effective support - or whether there's a conversation to be had!